Product Description

COMPANY INTRODUCTION

HangZhou Worth Engineering Technology Co., Ltd. founded in 2001 , Company is located in the Chinese ancient city — HangZhou. Our company has been engaged in producing custom made engineering accessories, OEM/ODM spare parts and industrial components for many years, including CHINAMFG parts and investment casting spare parts, forging parts, sheet metal stamping spare parts, machined parts and plastic parts, which are widely used in petrochemical, automobile, chemical, environmental protection , machinery, construction, agriculture, aerospace, marine hardware and other industries.

PE/PVC/ABS/PU/EPDM/NYLON/SILICONE PLASTIC INJECTION OR VACUUM FORMING AUTO SPARE PARTS

Model NO.:As per customer required

Material:NBR/FKM/Viton/Silicone/HNBR/EPDM/PP/PU/PVC/ABS/NYLON etc

Application:Machinery, Industrial Component, Electronic Product, Vehicle, Household Appliance Cross-Section Shape:Customized

Size:Customized

Color:Black,Red,Grey,Brown,Coffee etc

Workmanship:Plastic Injection Moulding/Vacumm Forming/Blow Molding

Surface:Smooth, Matt Finish, Glossy, as You Requirements

Working Temperature:-40~230 Celsius Degree

OEM/ODM:Customized

Performance:High Pressure

Eco-Friendly:Non-Tonix Mold Rubber Products

Function:Oil Prevention Sealing; Water Prevention Sealin

Trademark: NBR/FKM/Viton/Silicone/HNBR/EPDM/PP/PU/PVC/ABS/NYLON

Specification:ISO9001: 2015; TS16949; SGS

COMPANY EQUIPMENTS

TESTING EQUIPMENTS

THE PACKAGE AND SHIPMENT

CUSTOMERS

FAQ

Q1. How to customize products?

A2: Attach your drawings with details (material, surface treatment, quantity and special requirements etc).

Q2: Can you make the parts based on the sample?

A3: Yes, we could provide a rough cost and will measure and design the drawing according your sample.

Q3: Can my design be safe after sending it to you?

A5: We can CHINAMFG the NDA before you send it.

Q4. How long will it take to get the quotation?

A6: We will give you the quotation within 24 hours (Considering the time difference).

Q5. How does the company control the quality?

A7: Inspection product with professional equipment , like CMM, height gauge, caliper & micrometer,quadratic equipment .

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Shaping Mode: | Injection Mould |

|---|---|

| Surface Finish Process: | Mirror Polishing |

| Mould Cavity: | Multi Cavity |

| Plastic Material: | PA66+GF |

| Process Combination Type: | Single-Process Mode |

| Application: | Car, Furniture, Electronic, Hardware |

| Customization: |

Available

| Customized Request |

|---|

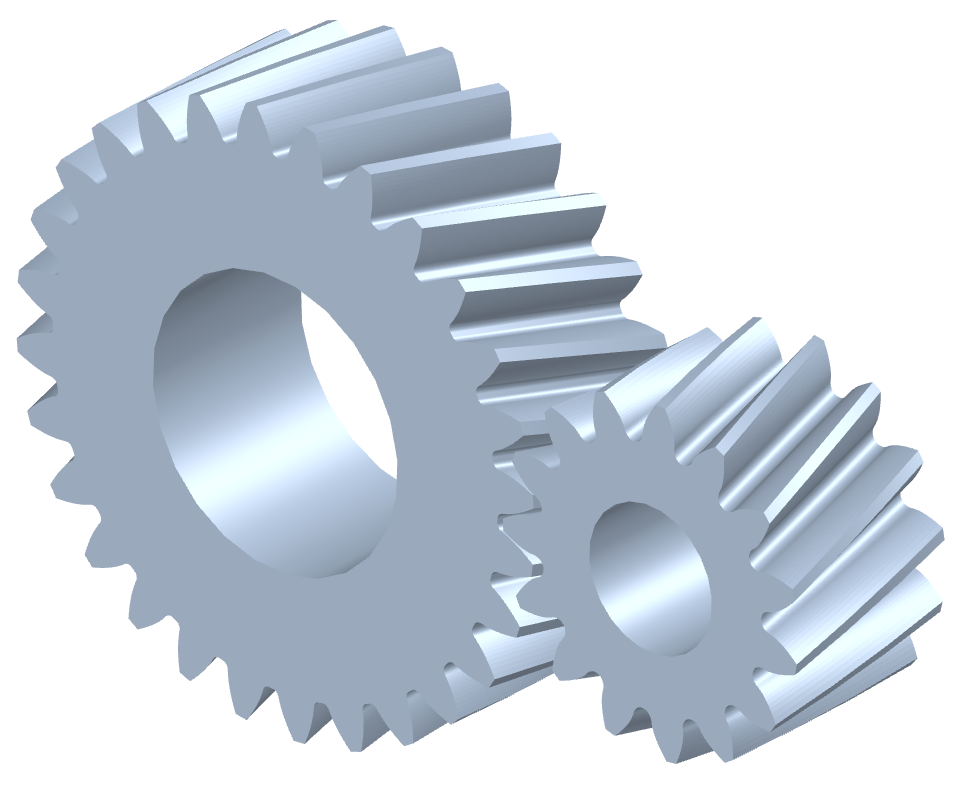

How do you maintain and service a helical gear system?

Maintaining and servicing a helical gear system is essential to ensure its long-term performance, reliability, and longevity. Proper maintenance practices help identify and address potential issues before they lead to gear failure or reduced efficiency. Here’s a detailed explanation of how to maintain and service a helical gear system:

- Regular Inspection: Perform regular visual inspections of the helical gear system to check for any signs of wear, damage, or misalignment. Inspect the gear teeth, shafts, bearings, and lubrication system for any abnormalities. Look for indications such as pitting, chipping, excessive tooth wear, or unusual noise or vibration during operation.

- Lubrication Maintenance: Ensure proper lubrication of the helical gears as per the manufacturer’s recommendations. Monitor lubricant levels, quality, and contamination. Periodically check and replenish or replace the lubricant as necessary. Follow the recommended lubrication intervals and use the appropriate lubricant type and viscosity for the operating conditions.

- Gear Cleaning: Keep the gear system clean and free from debris or contaminants. Regularly remove any accumulated dirt, dust, or foreign particles that may affect the gear performance. Use appropriate cleaning methods such as brushing, wiping, or compressed air to maintain a clean gear environment.

- Alignment Check: Misalignment can lead to premature gear failure and reduced efficiency. Periodically check the shaft alignment using precision alignment tools. Ensure that the shafts are properly aligned both radially and axially. If misalignment is detected, take corrective measures such as adjusting the shaft positions or using shims to reestablish proper alignment.

- Check Gear Meshing: Monitor the gear meshing to ensure proper tooth engagement and contact. Regularly inspect the tooth contact pattern to identify any irregularities or changes. If necessary, make adjustments to the gear position or shim thickness to achieve the desired tooth contact pattern and optimize gear performance.

- Bearing Maintenance: Check the condition of the bearings supporting the helical gears. Monitor for any signs of wear, damage, or inadequate lubrication. Replace worn-out or faulty bearings promptly to prevent further damage to the gear system. Follow the manufacturer’s guidelines for bearing maintenance, lubrication, and replacement.

- Vibration Analysis: Perform periodic vibration analysis to detect any abnormal vibration patterns that may indicate gear or bearing problems. Use vibration monitoring tools and techniques to identify the source and severity of the vibrations. If excessive vibrations are detected, investigate and rectify the underlying causes to prevent gear damage or failure.

- Temperature Monitoring: Monitor the temperature of the helical gear system during operation. Excessive heat can be an indication of inadequate lubrication, overloading, or other issues. Regularly measure and record the gear system’s operating temperature to identify any abnormal temperature rise and take appropriate action if necessary.

- Training and Documentation: Ensure that maintenance personnel are properly trained in helical gear system maintenance and servicing. Maintain detailed documentation of maintenance activities, including inspection records, lubrication schedules, and any repairs or replacements performed. This documentation helps track the gear system’s history and assists in troubleshooting and future maintenance planning.

- Consult with Experts: When in doubt or when dealing with complex gear systems, consult with gear manufacturers, industry experts, or experienced engineers for guidance on specific maintenance procedures or troubleshooting techniques. They can provide valuable insights and recommendations based on their expertise and experience.

By following these maintenance and servicing practices, you can ensure the optimal performance, reliability, and longevity of your helical gear system. Regular inspections, proper lubrication, alignment checks, and timely repairs or replacements are crucial for minimizing downtime, extending gear life, and maximizing the efficiency of the gear system.

What are the potential challenges in designing and manufacturing helical gears?

Designing and manufacturing helical gears can present various challenges that need to be addressed to ensure optimal performance and durability. Here’s a detailed explanation of the potential challenges encountered in designing and manufacturing helical gears:

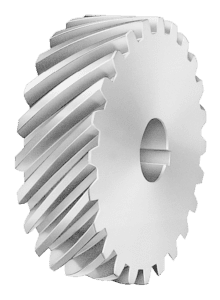

- Complex Geometry: The geometry of helical gears is more complex compared to other gear types. The helical tooth profile requires precise calculations and manufacturing techniques to achieve the desired gear performance. Designers must account for factors such as helix angle, lead angle, tooth shape modification, and tooth contact pattern optimization. The complex geometry adds challenges to both the design and manufacturing processes.

- Manufacturing Accuracy: Achieving the required manufacturing accuracy for helical gears can be challenging. The gear teeth must have precise profiles and dimensions to ensure proper meshing and load distribution. The manufacturing processes, such as gear cutting (e.g., hobbing or grinding), must be carefully controlled to achieve the desired tooth geometry, surface finish, and dimensional accuracy. Maintaining tight tolerances and minimizing manufacturing variations are crucial to ensure the gears meet the design specifications.

- Axial Thrust and Bearing Considerations: Helical gears generate axial thrust forces due to the helix angle. The axial thrust can affect gear performance and may require additional measures to properly manage. Adequate bearing selection and support systems must be designed to accommodate the axial loads and ensure smooth gear operation. Consideration should also be given to the potential thrust-induced axial movement and its impact on gear alignment and system performance.

- Noise and Vibration: Helical gears can produce noise and vibration during operation, particularly if not designed or manufactured correctly. Factors such as improper tooth contact, misalignment, or excessive gear backlash can contribute to increased noise and vibration levels. Designers and manufacturers must carefully analyze and optimize the gear geometry, tooth contact patterns, and manufacturing processes to minimize noise and vibration and ensure quieter operation.

- Lubrication Challenges: Proper lubrication is critical for the smooth operation and longevity of helical gears. However, the helical tooth profile can pose challenges for lubricant distribution. The inclined teeth create a sliding action that may affect lubricant film formation and retention. Ensuring adequate lubrication to all gear surfaces, including the tooth flanks and root fillets, becomes important. Designing efficient lubrication systems and selecting appropriate lubricants that can withstand the sliding action and provide sufficient film thickness is crucial.

- Heat Dissipation: Helical gears can generate significant heat during operation, especially at high speeds or under heavy loads. Effective heat dissipation is essential to prevent overheating and premature wear. Designers and manufacturers need to consider heat dissipation mechanisms, such as proper housing design, cooling methods, and suitable materials with good thermal conductivity. Adequate ventilation and lubrication systems should also be designed to facilitate heat dissipation and maintain optimum operating temperatures.

- Tooling and Equipment: Manufacturing helical gears often requires specialized tooling and equipment. The gear cutting processes, such as hobbing or grinding, may necessitate specific tools, cutters, or grinding wheels. These tools must be properly selected, calibrated, and maintained to achieve accurate tooth profiles and finishes. The availability of suitable tooling and equipment, as well as the expertise to operate and maintain them, can be a challenge for gear manufacturers.

- Cost Considerations: Designing and manufacturing helical gears can involve higher costs compared to simpler gear types. The complexity of gear geometry, precision manufacturing requirements, specialized tooling, and additional considerations such as bearing support or noise reduction measures can contribute to increased production costs. Balancing the desired gear performance with cost considerations can be challenging for designers and manufacturers.

By addressing these potential challenges through careful design, precise manufacturing processes, and proper selection of materials and lubrication, engineers can overcome the complexities associated with designing and manufacturing helical gears and ensure high-quality gears that meet performance requirements and deliver long-term reliability.

Are there different types of helical gears available?

Yes, there are different types of helical gears available to meet specific application requirements. Here’s a detailed explanation of some common types of helical gears:

- Parallel Helical Gears: Parallel helical gears are the most commonly used type of helical gears. In this configuration, two helical gears with parallel axes are meshed together. They transmit power and motion between parallel shafts. Parallel helical gears provide smooth operation, high load-carrying capacity, and efficient power transmission.

- Double Helical Gears (Herringbone Gears): Double helical gears, also known as herringbone gears, have two sets of helical teeth that are placed in a V-shaped configuration. The V-shaped teeth face each other, with a groove or gap in the middle. This design cancels out the axial thrust that is generated by the helical gear’s inclined teeth. Double helical gears are often used in applications that require high torque transmission and axial load balancing, such as heavy machinery and marine propulsion systems.

- Crossed Helical Gears (Screw Gears): Crossed helical gears, also referred to as screw gears, involve the meshing of two helical gears with non-parallel and non-intersecting axes. The gears are oriented at an angle to each other, typically 90 degrees. Crossed helical gears are used in applications where shafts intersect or when a compact and non-parallel gear arrangement is required. They are commonly found in hand drills, speedometers, and some mechanical watches.

- Skew Gears: Skew gears are a type of helical gear in which the gear teeth are cut at an angle to the gear axis. The angle of the teeth can vary, allowing for different degrees of skew. Skew gears are used in applications where the axes of the mating gears are neither parallel nor intersecting. They can transmit power between non-parallel and non-intersecting shafts while accommodating misalignments.

- Helical Rack and Pinion: A helical rack and pinion system consists of a helical gear (pinion) that meshes with a linear gear (rack). The pinion is a cylindrical gear with helical teeth, while the rack is a straight bar with teeth that mesh with the pinion. This configuration is commonly used in applications that require linear motion, such as CNC machines, robotics, and rack and pinion steering systems in automobiles.

- Variable Helix Gears: Variable helix gears have a unique tooth profile where the helix angle varies along the face width of the gear. The varying helix angle helps to reduce noise, vibration, and backlash while maintaining smooth operation and load distribution. These gears are often used in high-performance applications where noise reduction and precise motion control are critical.

The specific type of helical gear used depends on factors such as the application requirements, load conditions, space limitations, and desired performance characteristics. Manufacturers often provide various options and customizations to meet specific needs.

It’s important to note that the design and manufacturing of helical gears require careful consideration of factors such as tooth profile, helix angle, lead angle, module or pitch, pressure angle, and material selection. These factors ensure proper gear meshing, load distribution, and efficient power transmission.

In summary, different types of helical gears, including parallel helical gears, double helical gears (herringbone gears), crossed helical gears (screw gears), skew gears, helical rack and pinion systems, and variable helix gears, are available to cater to a wide range of applications. Each type has its unique characteristics and advantages, allowing for optimized performance and reliable power transmission in various industries and machinery.

editor by CX 2024-04-12